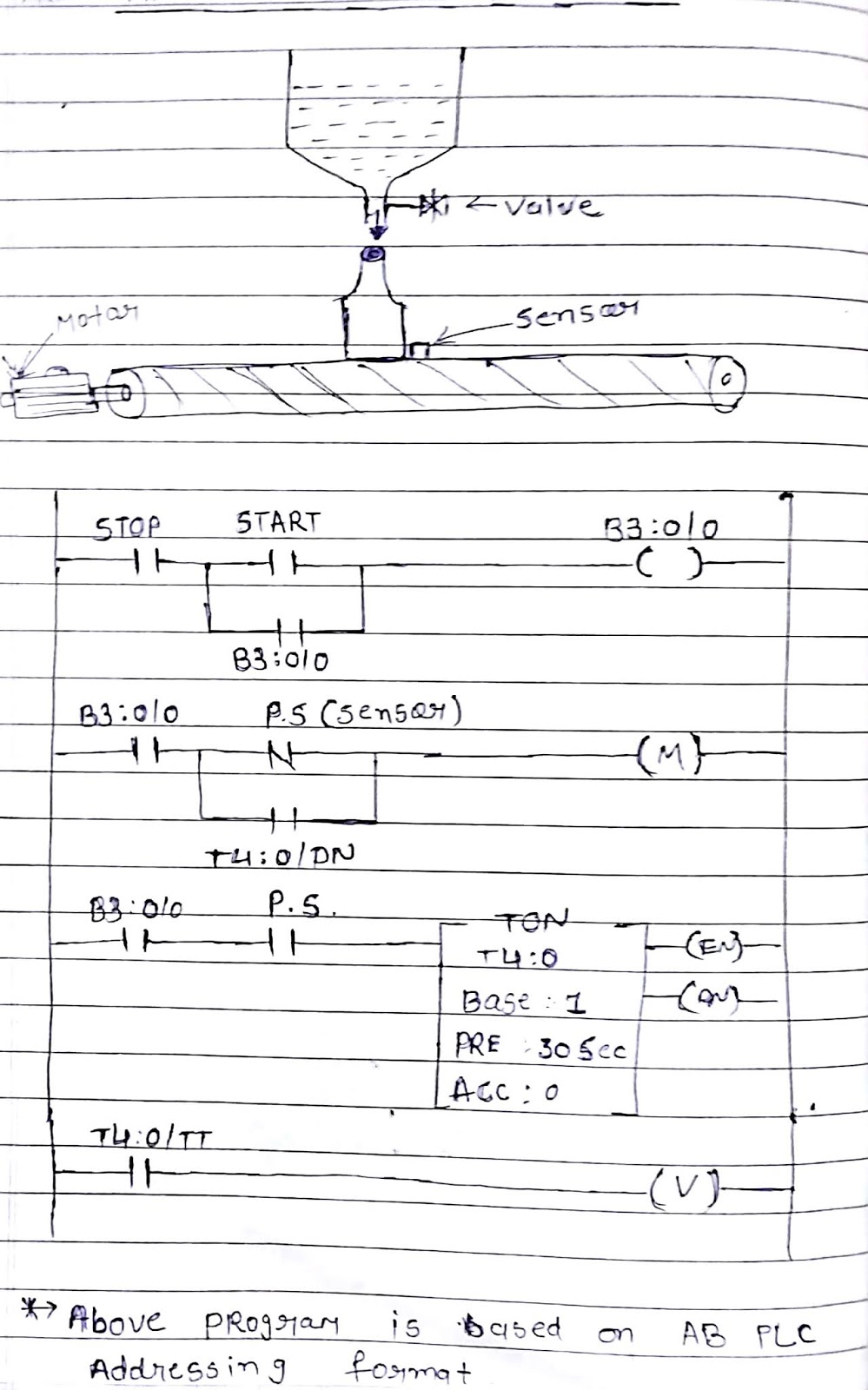

Bottle Filling Machine Ladder Diagram [diagram] Ladder Logic

Plc bottle filling ladder logic Bottle filling plc ladder logic Bottle line filling and capping system using plc ladder logic

[DIAGRAM] Ladder Logic Diagram For Bottle Filling System - MYDIAGRAM.ONLINE

Bottle filling process plc program Bottle line filling and capping system using plc ladder logic Automatic bottle filling system using plc linguagem ladder, ladder

Patent no. 440916a: bottle filling machine

Plc ladder continuousFilling bottle plc system application process implementation gif Programmable logic controller for bottle filling machine[diagram] ladder logic diagram for bottle filling system.

Bottle filling and capping project using plc ladder logicFilling bottle plc system program pressure maintain head diagram problem sanfoundry advertisement Automatic bottle filling and capping machine usingPlc implementation of the bottle-filling application.

Me-vs-engineeringlife: filling tank (plc)

Bottle filling plc ladder logicAutomatic bottle filling system using plc(scada simulation) Water machine filling bottle plant bottling mineral automatic diagram layout making flow chart line carbonated drink packaging workshop production bottledBottle line filling and capping system using plc ladder logic.

Automatic bottle filling system using plcFilling bottle plc system automatic using scada simulation Filling ladder plc instrumentation nutshellDesign of a flexible automated bottle filling machine -prototype.

![[DIAGRAM] Ladder Logic Diagram For Bottle Filling System - MYDIAGRAM.ONLINE](https://i2.wp.com/electrical-engineering-portal.com/wp-content/uploads/plc-implementation-bottle-filling-app.gif)

Filling bottle hmi application plc ladder use logic tricks programmer many

Bottle line assembly using plc ladder logic programmingBottle filling system using plc and scada part-1 plc ladder, 43% off Continuous bottle filling system using plc program – instrumentationPlc ladder diagram bottle filling plant.

Instrumentation in a nutshell: application of plc in bottle filling process[diagram] instrument loop diagrams guidance programmatic and facility Filling bottle machine patentPlc filling.

Bottle line filling and capping system using plc ladder logic

Filling plc bottling ladder logic conveyor project simulation instrumentationtools automation equippedAutomatic bottle filling system using arduino Design of a flexible automated bottle filling machine -prototype[pdf] automatic liquid filling to bottles of different height using.

Automatic bottle filling plc programAutomatic bottle filling & capping machine using plc ladder logic Hmi bottle filling applicationAutomatic bottle filling machine with workshop layout diagram.

Ladder filling logic

Plc program to maintain the pressure head in a bottle filling systemLadder logic for bottle filling system Instrumentation in a nutshell: application of plc in bottle filling processInstrumentation nutshell.

.

Automatic Bottle Filling Machine With Workshop Layout Diagram - Buy

PLC implementation of the bottle-filling application

Bottle Filling Process PLC program - INSIDE AUTOMATION

Automatic Bottle Filling system using PLC(Scada simulation) - YouTube

Bottle Line Filling and Capping system using PLC Ladder Logic - The

Continuous bottle filling system using PLC Program – Instrumentation

![[PDF] AUTOMATIC LIQUID FILLING TO BOTTLES OF DIFFERENT HEIGHT USING](https://i2.wp.com/d3i71xaburhd42.cloudfront.net/a998d083edd95d2eafad5f3f43f8026c711e9dd6/2-FigureI-1.png)

[PDF] AUTOMATIC LIQUID FILLING TO BOTTLES OF DIFFERENT HEIGHT USING